In the textile industry, ensuring the quality and durability of fabrics is critical. One of the essential tests used to measure fabric strength is the bursting strength test. This test evaluates how much pressure a fabric can withstand before it ruptures, making it crucial for manufacturers aiming to deliver high-quality products. The Pneumatic Burst Tester plays a vital role in this testing process, providing accurate and reliable results.

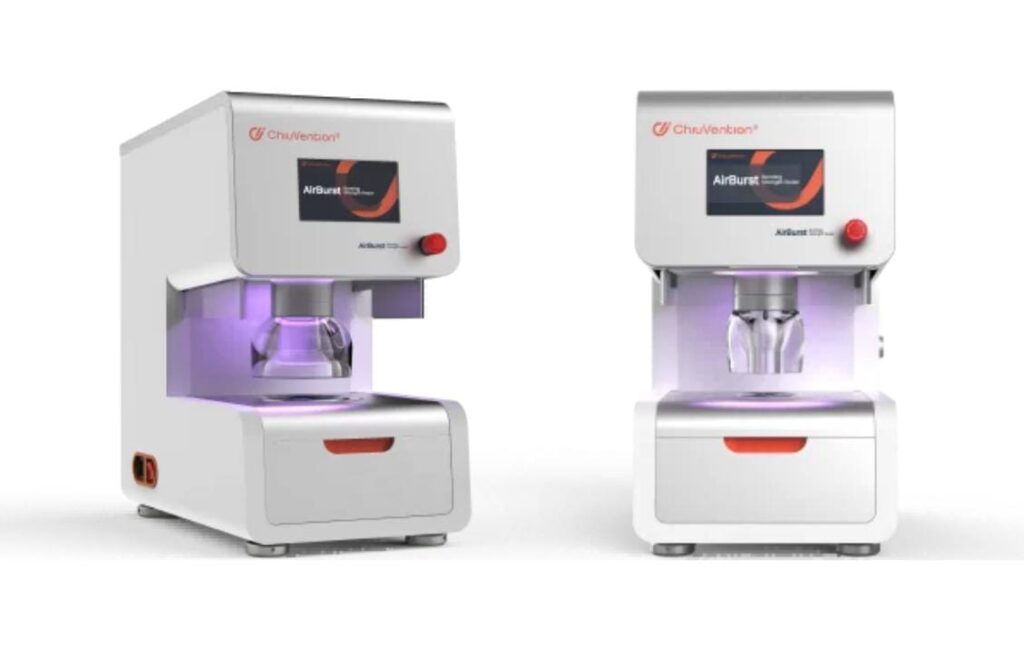

What is a Pneumatic Burst Tester?

A Pneumatic Burst Tester is a sophisticated device designed to assess the bursting strength of various fabrics. It uses pneumatic pressure to apply force evenly across a fabric sample, pushing against a diaphragm until the fabric bursts. This method offers a high level of precision, ensuring that the results are consistent and reliable.

By employing this testing equipment, manufacturers can evaluate the durability of their materials, which is essential for producing textiles that meet industry standards and consumer expectations.

The Significance of Burst Strength Testing

Conducting bursting strength tests is essential for several reasons:

- Quality Control: Regularly testing fabrics for burst strength helps manufacturers maintain consistent quality throughout their production processes. By utilizing a pneumatic bursting strength tester, companies can quickly identify any issues and make necessary adjustments.

- Regulatory Compliance: Many industries have specific standards that fabrics must meet regarding durability and performance. Burst strength testing helps ensure compliance with these regulations, avoiding costly penalties and recalls.

- Consumer Safety: Fabrics used in safety-critical applications, such as automotive interiors or medical textiles, must be able to withstand high pressure without failure. Bursting strength testing is crucial for ensuring that these materials can perform reliably under stress.

Factors Influencing Bursting Strength of Fabric

Several factors can affect a fabric’s bursting strength, including:

- Fabric Composition: The type of fibres used in a fabric can significantly influence its strength. Synthetic fibres, such as polyester or nylon, often exhibit higher bursting strength than natural fibres like cotton or linen.

- Weave Pattern: The construction of the fabric, including its weave pattern, can enhance or reduce its bursting strength. Tighter weaves generally provide better resistance against bursting.

- Environmental Conditions: Factors such as humidity and temperature can also impact a fabric’s performance, potentially affecting its bursting strength over time.

Conclusion

The Pneumatic Burst Tester is an essential tool for textile manufacturers committed to ensuring the quality and durability of their products. By understanding the importance of bursting strength testing and the factors that influence it, businesses can improve their fabric quality, ensure regulatory compliance, and prioritize consumer safety.

To enhance your fabric testing processes and ensure the highest quality standards, consider investing in a Pneumatic Burst Tester. This investment can lead to significant improvements in product reliability and customer satisfaction.